Introduction to Auto Main Failures (AMF) Panels

An Auto Main Failures (AMF) panel, also known as an Automatic Transfer Switch (ATS) panel, is an electrical control system designed to automatically transfer a load from a primary power source (typically the mains utility supply) to a backup power source (usually a generator) when the primary source fails or experiences a significant voltage drop. Once the main power is restored, the AMF panel automatically switches the load back to the primary source and shuts down the generator. This seamless transition ensures an uninterrupted power supply to critical equipment and systems.

Purpose and Importance

The primary purpose of an AMF panel is to provide a reliable and uninterrupted power supply to essential loads during a mains power outage. This is particularly important in applications where power interruptions can have severe consequences, such as:

• Hospitals: To maintain life-support systems, operating rooms, and critical medical equipment.

• Data Centers: To prevent data loss, system downtime, and financial losses.

• Telecommunications: To ensure continuous communication services.

• Emergency Services: To power fire stations, police stations, and emergency responsecenters.

• Industrial Facilities: To prevent production downtime, equipment damage, and safetyhazards.

• Commercial Buildings: To maintain essential services like lighting, security systems, and elevators

Key Components of an AMF Panel

An AMF panel consists of several key components that work together to ensure automatic power transfer:

1. Controller: The brain of the AMF panel, responsible for monitoring the main power supply, detecting failures, initiating the generator start sequence, and controlling the transfer switches. Modern controllers often include microprocessors and digital displays for easy monitoring and configuration.

2. Transfer Switch: A heavy-duty switch that automatically transfers the load between the main power supply and the generator. Transfer switches can be either electromechanical (contactor-based) or solid-state (using silicon-controlled rectifiers or thyristors).

3. Circuit Breakers: Provide overcurrent protection for both the main power supply and the generator. They are essential for preventing damage to the equipment and ensuring safety.

4. Contactors/Relays: Used to control various functions within the AMF panel, such as starting and stopping the generator, controlling the transfer switch, and providing alarm signals.

5. Voltage and Frequency Monitoring Relays: Continuously monitor the voltage and frequency of the main power supply. If these parameters fall outside acceptable limits, the controller initiates the transfer sequence.

6. Generator Start/Stop Control: Interfaces with the generator's control system to start and stop the generator automatically.

7. Battery Charger: Keeps the generator's starting battery fully charged to ensure reliable starting.

8. Wiring and Enclosure: High-quality wiring and a robust enclosure are essential for ensuring the reliability and safety of the AMF panel. The enclosure should be properly grounded and provide protection against environmental factors.

9. Display and Indicators: Provides visual indication of the system status, including the availability of the main power supply, the generator status, and any alarm conditions.

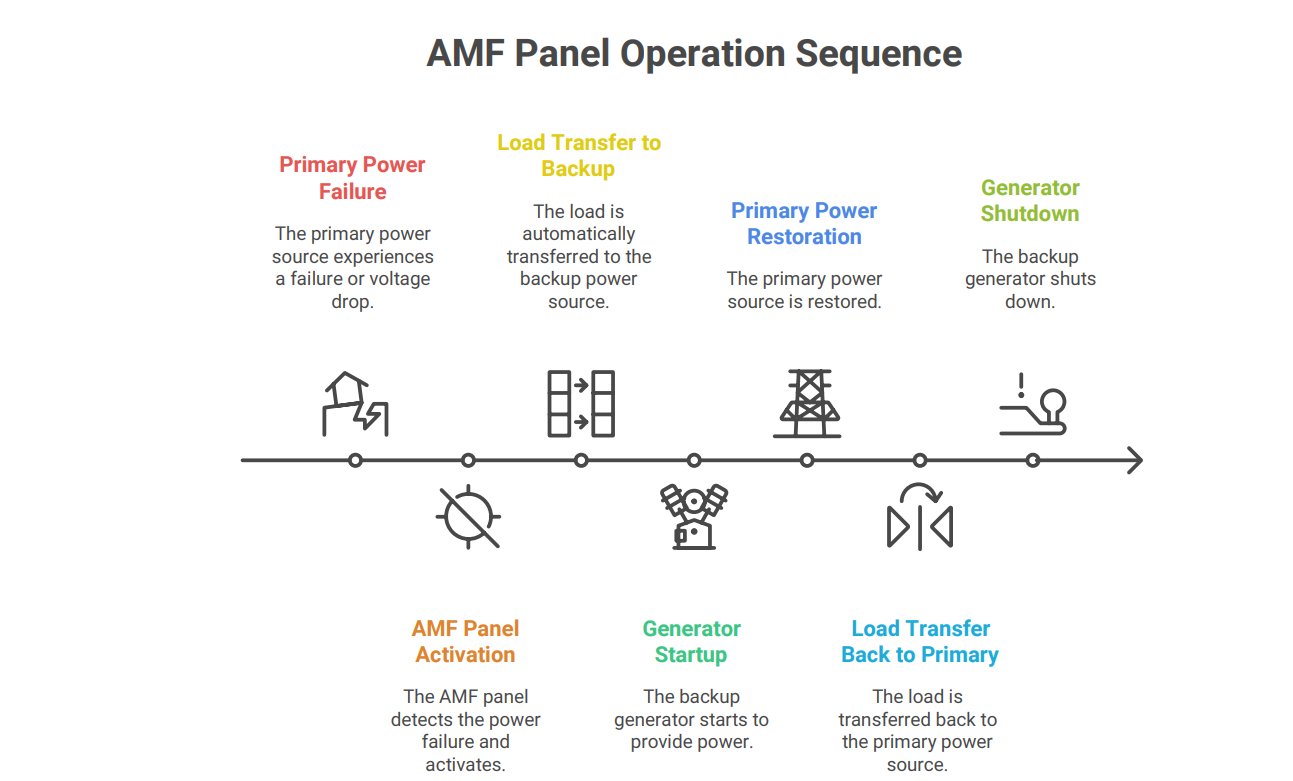

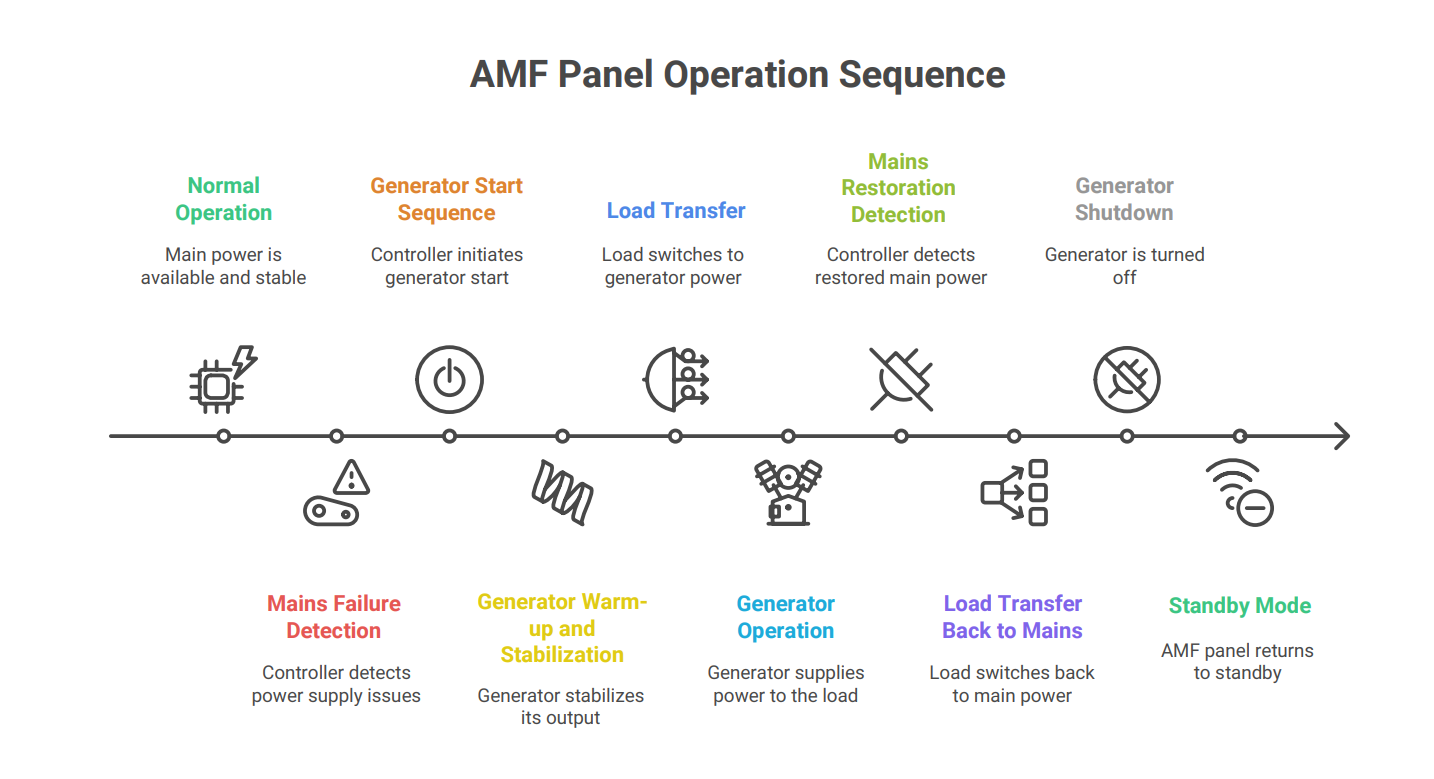

Operation of an AMF Panel

The operation of an AMF panel can be summarized in the following steps:

1. Normal Operation: Under normal conditions, the main power supply is available and within acceptable voltage and frequency limits. The AMF panel keeps the load connected to the main power supply. The generator is in standby mode.

2. Mains Failure Detection: The controller continuously monitors the main power supply. If the voltage or frequency falls outside the preset limits (due to a power outage, voltage sag, or other fault), the controller detects the failure.

3. Generator Start Sequence: Upon detecting a mains failure, the controller initiates the generator start sequence. This typically involves sending a start signal to the generator's control system.

4. Generator Warm-up and Stabilization: The generator starts and runs through a warm-up period to stabilize its voltage and frequency. The controller monitors the generator's output to ensure it is within acceptable limits.

5. Load Transfer: Once the generator's output is stable, the controller activates the transfer switch to disconnect the load from the main power supply and connect it to the generator.

6. Generator Operation: The generator continues to supply power to the load until the main power supply is restored.

7. Mains Restoration Detection: The controller continuously monitors the main power supply. When the voltage and frequency return to normal and remain stable for a predetermined period, the controller detects the restoration of the main power.

8. Load Transfer Back to Mains: The controller activates the transfer switch to disconnect the load from the generator and connect it back to the main power supply.

9. Generator Shutdown: After the load has been successfully transferred back to the main power supply, the controller sends a stop signal to the generator, shutting it down.

10. Standby Mode: The AMF panel returns to its normal standby mode, ready to respond to the next mains failure.

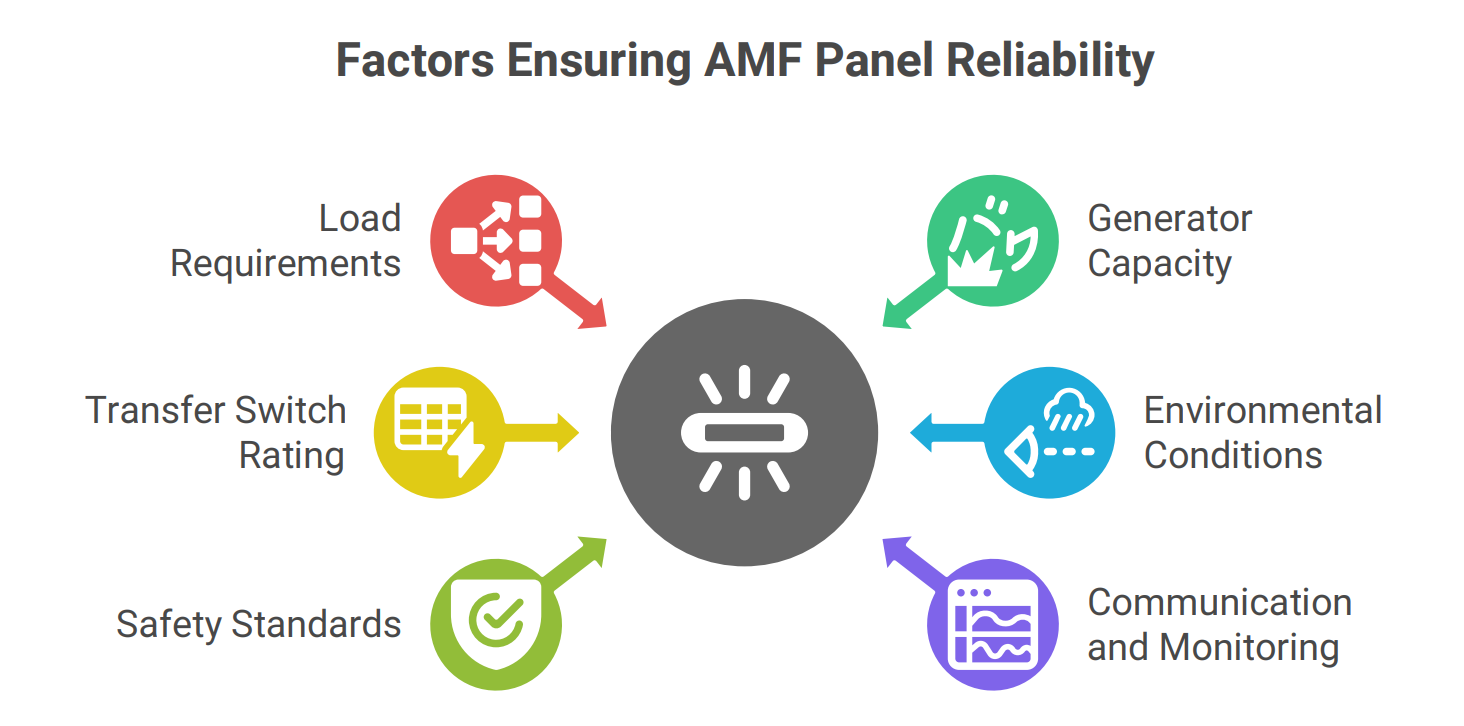

Design Considerations

When designing an AMF panel, several factors must be considered to ensure optimal performance and reliability:

• Load Requirements: The AMF panel must be sized to handle the total load it will be supplying. This includes considering the inrush current of motors and other inductive loads.

• Generator Capacity: The generator must have sufficient capacity to supply the load and handle any additional loads that may be added in the future.

• Transfer Switch Rating: The transfer switch must be rated to handle the full load current and voltage.

• Environmental Conditions: The AMF panel must be designed to withstand the environmental conditions in which it will be installed, including temperature, humidity,and dust.

• Safety Standards: The AMF panel must comply with all applicable safety standards and regulations.

• Communication and Monitoring: Modern AMF panels often include communication interfaces for remote monitoring and control. This allows operators to monitor the system status, receive alarms, and perform remote troubleshooting.

Installation and Maintenance

Proper installation and maintenance are essential for ensuring the reliability of an AMF panel:

• Installation: The AMF panel should be installed by qualified electricians in accordance with the manufacturer's instructions and all applicable electrical codes.

• Testing: After installation, the AMF panel should be thoroughly tested to ensure it is functioning correctly. This includes testing the automatic transfer function, the generator start sequence, and the alarm system.

• Preventive Maintenance: Regular preventive maintenance should be performed to keep the AMF panel in good working condition. This includes inspecting the wiring, cleaning the components, testing the battery, and verifying the operation of the transfer switch.

• Troubleshooting: If the AMF panel malfunctions, it should be promptly troubleshooting by a qualified technician. Common problems include faulty controllers, transfer switch failures, and generator starting problems.

Conclusion

Auto Main Failures (AMF) panels are essential components for ensuring continuous power supply in critical applications. By automatically switching to a backup generator when the main power source fails, AMF panels prevent power interruptions and protect essential equipment and systems. Proper design, installation, maintenance, and troubleshooting are crucial for ensuring the reliability and performance of AMF panels. As technology advances, modern AMF panels are becoming more sophisticated, offering enhanced monitoring, control, and communication capabilities.