Introduction to VFD and Soft Starter Panels

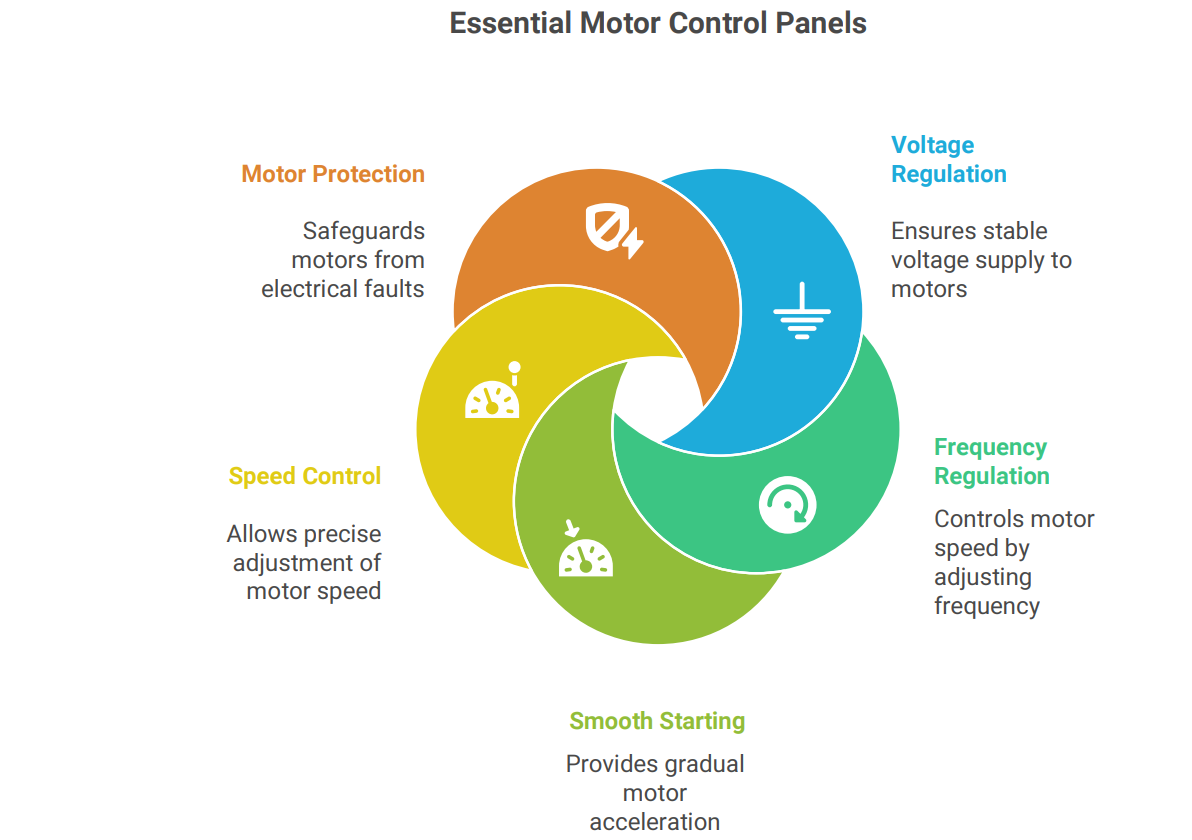

VFD and Soft Starter panels are crucial components in modern industrial and commercial applications where precise motor control and energy efficiency are paramount. These panels house the necessary equipment to regulate the voltage and frequency supplied to electric motors, enabling smooth starting, speed control, and protection

Variable Frequency Drive (VFD) Panels

Purpose and Functionality

A VFD panel houses a Variable Frequency Drive (also known as an Adjustable Speed Drive or Inverter), which controls the speed of an AC motor by varying the frequency and voltage supplied to it. This allows for precise control over motor speed and torque, optimizing performance and reducing energy consumption.

Key Components of a VFD Panel

VFD Unit: The core component that converts fixed-frequency, fixed-voltage AC power to a variable-frequency, variable-voltage output.

• Input Disconnect: A circuit breaker or switch to isolate the VFD from the power supply for maintenance and safety.

• Input Fuses/Circuit Breakers: Provide overcurrent protection for the VFD.

• Line Reactor/Choke: Reduces harmonics generated by the VFD and protects it from voltage spikes.

• EMC/RFI Filter: Minimizes electromagnetic interference (EMI) and radio frequency interference (RFI) emitted by the VFD.

• Output Reactor/Filter (Optional): Reduces voltage reflections and harmonics on the motor side, especially for long motor cables.

• Control Wiring and Terminals: Facilitate connections for control signals, feedback signals, and communication interfaces.

• Cooling System: Fans or air conditioners to maintain the VFD within its operating temperature range.

• Enclosure: A protective enclosure (NEMA rated) to house all components and protect them from environmental factors.

• Human-Machine Interface (HMI): A display and keypad for monitoring and controlling the VFD.

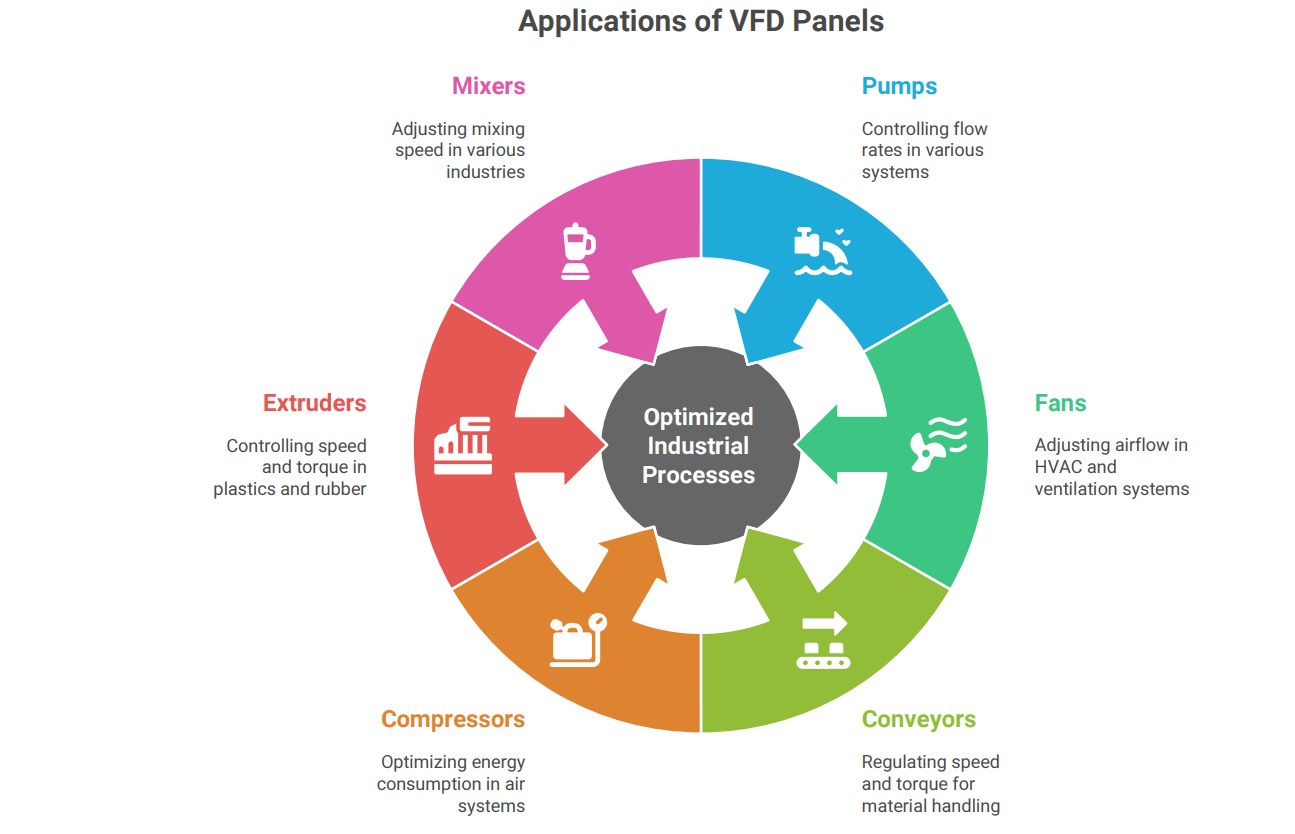

Applications of VFD Panels

• Pumps: Controlling flow rates in water and wastewater treatment plants, irrigation systems, and industrial processes.

• Fans: Adjusting airflow in HVAC systems, ventilation systems, and industrial exhaust systems.

• Conveyors: Regulating speed and torque for material handling in manufacturing and logistics.

• Compressors: Optimizing energy consumption in air compressors and refrigeration systems.

• Extruders: Controlling the speed and torque of extruders in plastics and rubber industries.

• Mixers: Adjusting mixing speed in chemical, food, and pharmaceutical industries.

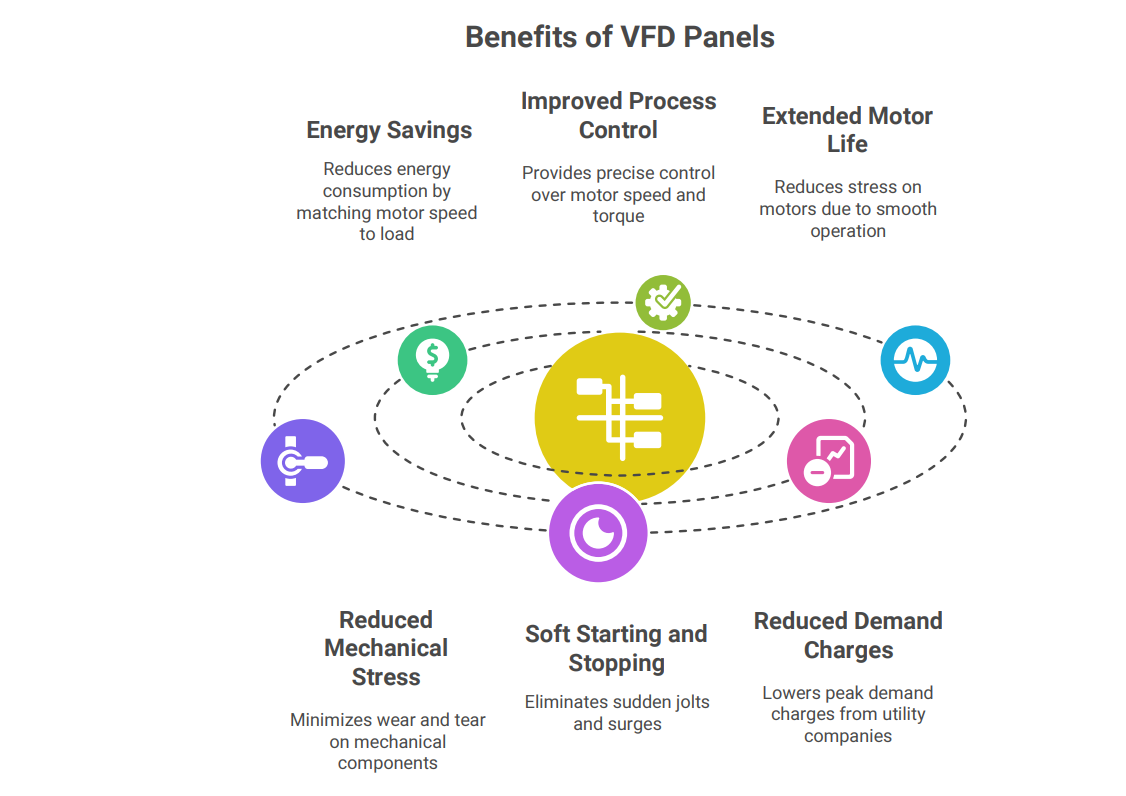

Advantages of Using VFD Panels

• Energy Savings: Reduced energy consumption by matching motor speed to actual load requirements.

• Improved Process Control: Precise control over motor speed and torque for optimized process performance.

• Extended Motor Life: Reduced stress on motors due to smooth starting and stopping.

• Reduced Mechanical Stress: Minimizes wear and tear on mechanical components such as belts, gears, and bearings.

• Soft Starting and Stopping: Eliminates sudden jolts and surges, preventing damage to equipment.

• Reduced Demand Charges: Lower peak demand charges from the utility company

Soft Starter Panels

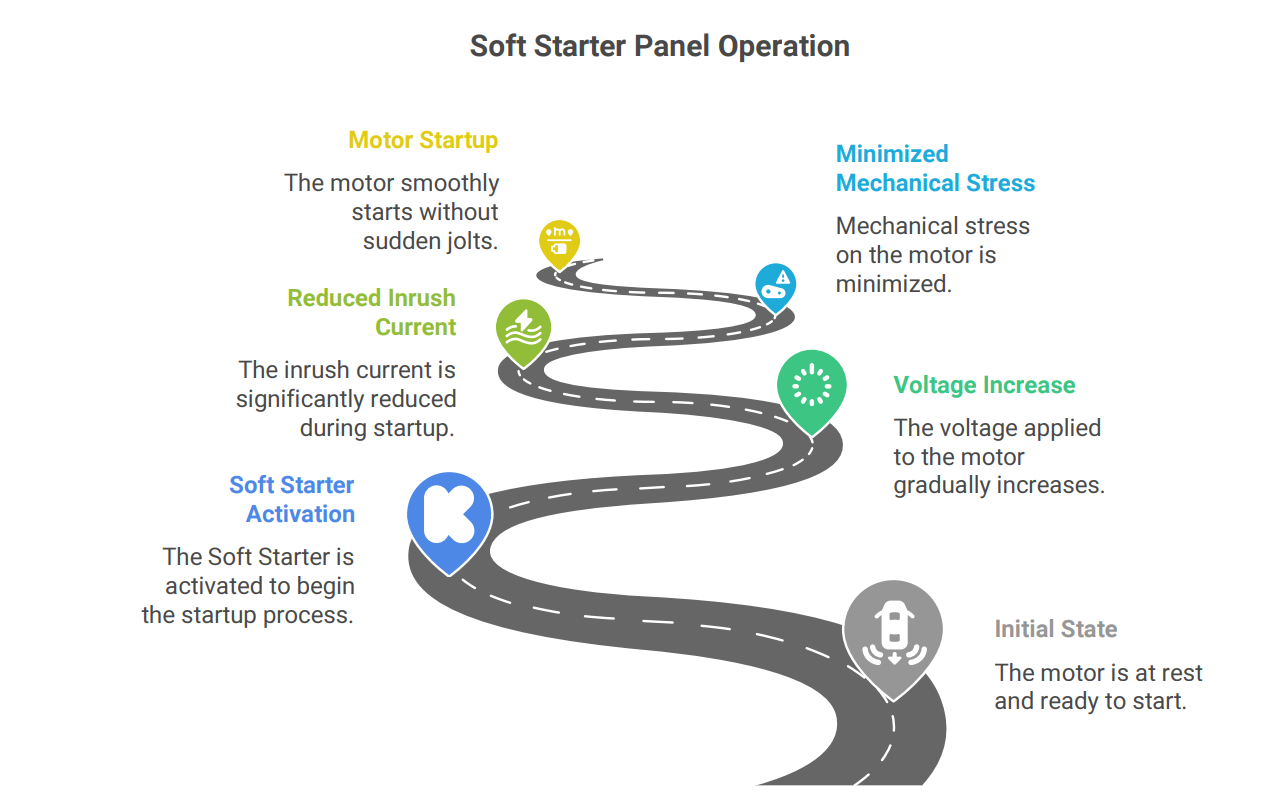

Purpose and Functionality

A Soft Starter panel houses a Soft Starter, which gradually increases the voltage applied to an AC motor during startup. This reduces the inrush current and mechanical stress associated with traditional across-the-line starting.

Key Components of a Soft Starter Panel

• Soft Starter Unit: The core component that controls the voltage applied to the motor during startup and shutdown.

• Input Disconnect: A circuit breaker or switch to isolate the Soft Starter from the power supply.

• Input Fuses/Circuit Breakers: Provide overcurrent protection for the Soft Starter.

• Bypass Contactor: A contactor that bypasses the Soft Starter after the motor has reached full speed, minimizing heat generation.

• Control Wiring and Terminals: Facilitate connections for control signals, feedback signals, and communication interfaces.

• Cooling System: Fans to dissipate heat generated by the Soft Starter.

• Enclosure: A protective enclosure (NEMA rated) to house all components.

• Human-Machine Interface (HMI): A display and keypad for monitoring and controlling the Soft Starter.

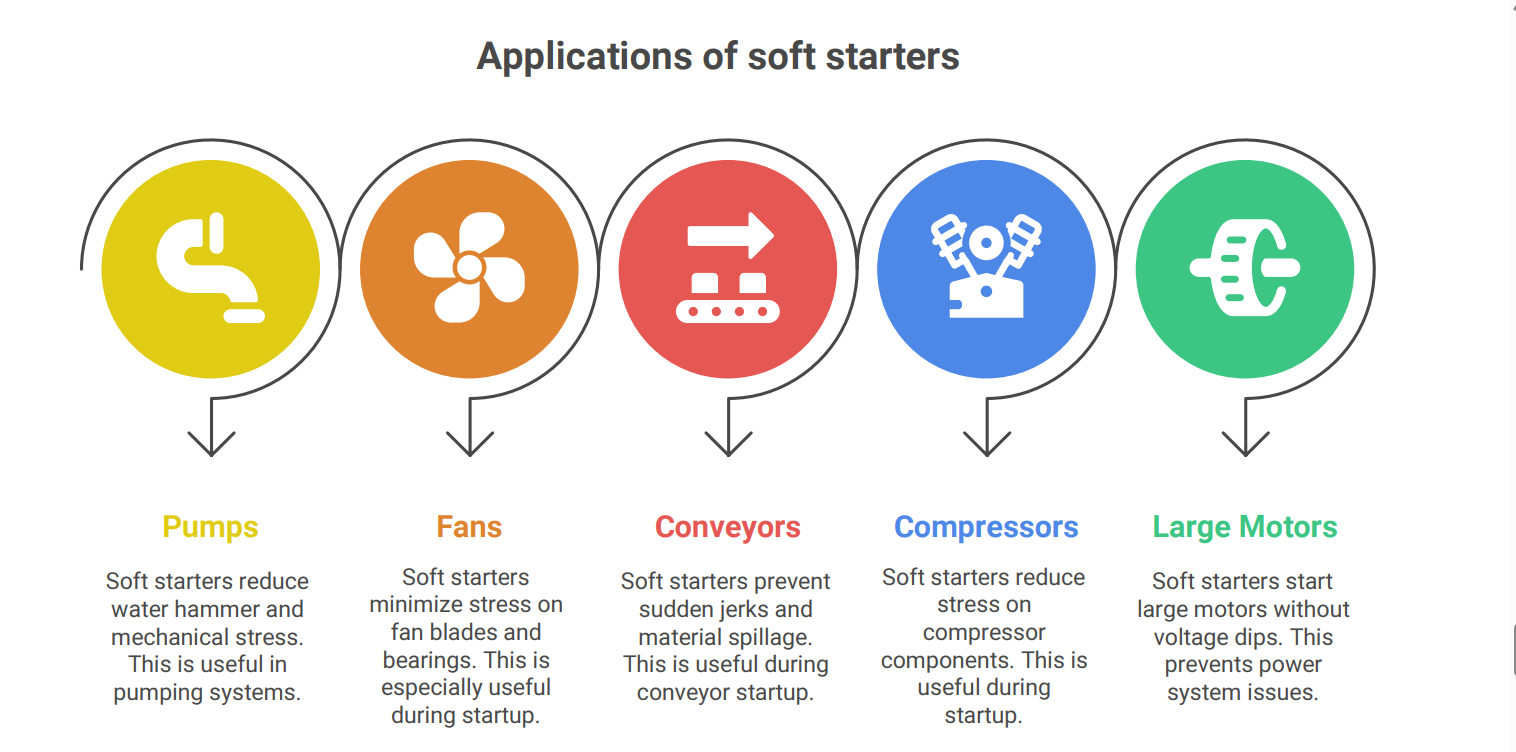

Applications of Soft Starter Panels

• Pumps: Reducing water hammer and mechanical stress in pumping systems.

• Fans: Minimizing stress on fan blades and bearings during startup.

• Conveyors: Preventing sudden jerks and material spillage during conveyor startup.

• Compressors: Reducing stress on compressor components during startup.

• Large Motors: Starting large motors without causing voltage dips in the power system.

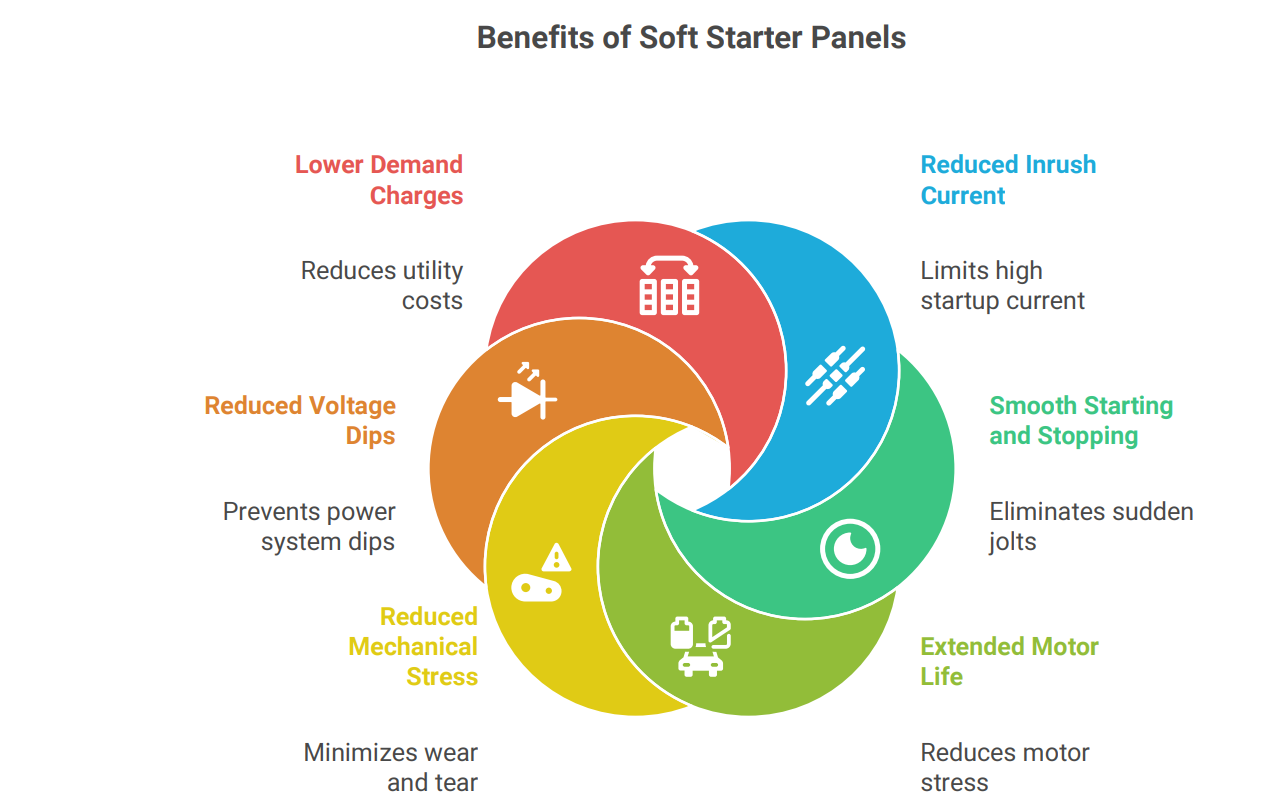

Advantages of Using Soft Starter Panels

• Reduced Inrush Current: Limits the high inrush current associated with across-the-line starting.

• Smooth Starting and Stopping: Eliminates sudden jolts and surges, preventing damage to equipment.

• Extended Motor Life: Reduced stress on motors due to smooth starting and stopping.

• Reduced Mechanical Stress: Minimizes wear and tear on mechanical components.

• Reduced Voltage Dips: Prevents voltage dips in the power system during motor startup.

• Lower Demand Charges: Reduced peak demand charges from the utility company compared to DOL starting.