Introduction to Motor Control Centers (MCCs)

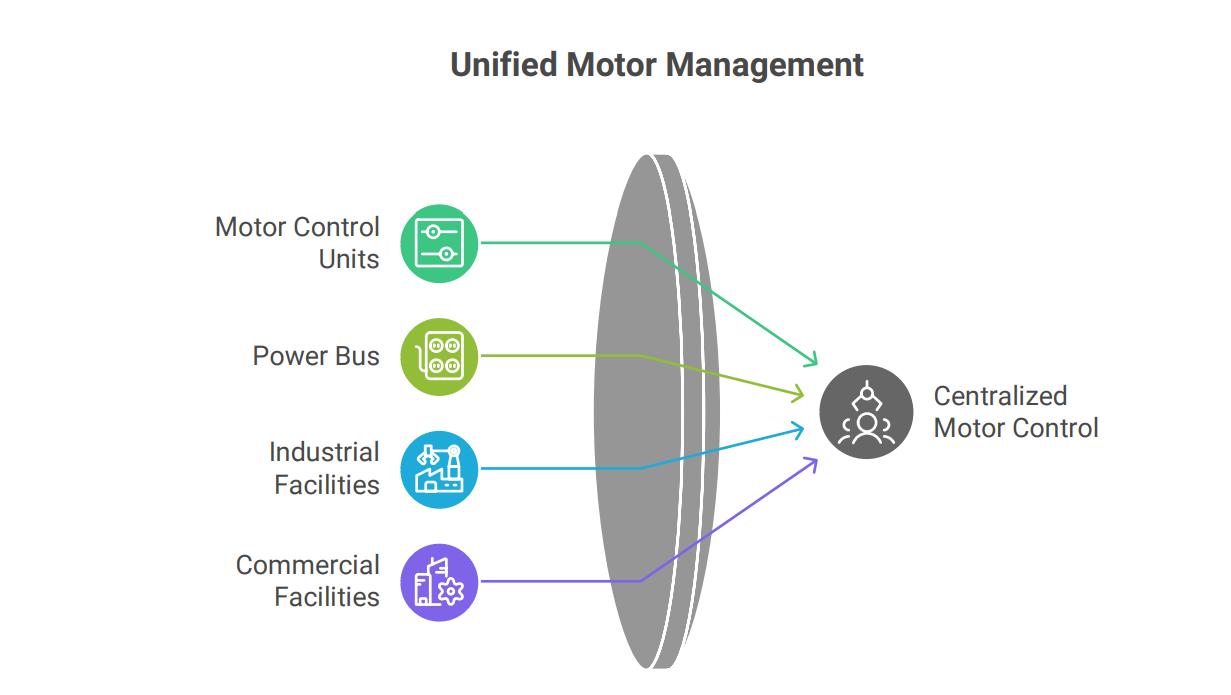

A Motor Control Center (MCC) is an assembly of one or more enclosed sections having a common power bus and principally containing motor control units. These units contain starters, fuses, circuit breakers, and other control devices. MCCs are used in industrial and large commercial facilities where many electric motors need to be controlled from a central location. They provide a convenient and organized way to manage motor starters, overload protection, and disconnects for a large number of motors.

Purpose of MCCs

The primary purposes of an MCC are:

• Centralized Motor Control: To provide a central location for controlling and monitoring multiple electric motors.

• Motor Protection: To protect motors from overloads, short circuits, and other electrical faults.

• Power Distribution: To distribute power to individual motor starters and control devices.

• Safety: To provide a safe and reliable means of disconnecting power to motors for maintenance and repair.

• Automation: To integrate with automation systems for remote control and monitoring of motors

Components of an MCC

A typical MCC consists of the following components:

Incoming Line Section: This section provides the main power connection to the MCC. It includes a main circuit breaker or fusible disconnect switch to protect the entire MCC.

• Vertical Bus: The vertical bus is a set of conductors that run vertically through the MCC, distributing power to the individual motor control units.

• Horizontal Bus: The horizontal bus connects the vertical bus to the individual motor control units.

• Motor Control Units (Buckets): These are individual compartments that contain the motor starter, overload protection, and disconnect devices for a single motor.

• Starters: Motor starters are used to start and stop motors. They typically include a contactor, overload relay, and control transformer.

• Overload Relays: Overload relays protect motors from overheating due to excessive current draw.

• Circuit Breakers or Fuses: These devices provide short circuit protection for the motor and the motor control unit.

• Disconnect Switches: Disconnect switches allow for manual disconnection of power to the motor for maintenance and repair.

• Control Transformers: Control transformers provide the necessary voltage for the control circuits within the motor control unit.

• Control Wiring: Control wiring connects the various components within the motor control unit and provides the necessary signals for control and monitoring.

• Pilot Devices: Pilot devices, such as pushbuttons, selector switches, and indicating lights, are used to control and monitor the motor.

• Programmable Logic Controllers (PLCs): PLCs can be integrated into MCCs for advanced control and automation of motors.

• Communication Modules: Communication modules allow the MCC to communicate with other devices and systems, such as SCADA systems.

Applications of MCCs

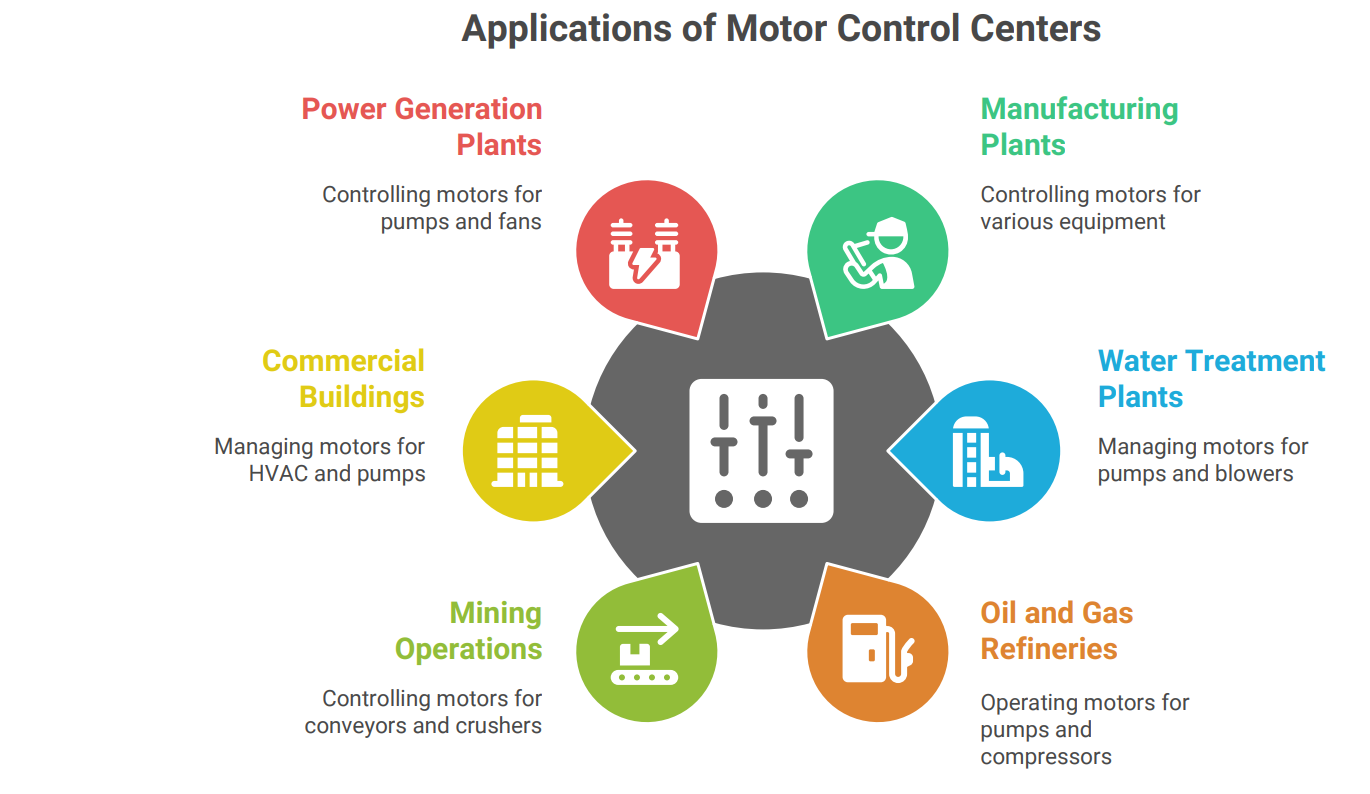

MCCs are used in a wide range of industrial and commercial applications, including:

• Manufacturing Plants: Controlling motors for pumps, fans, compressors, conveyors, and other equipment.

• Water and Wastewater Treatment Plants: Controlling motors for pumps, blowers, and other equipment.

• Oil and Gas Refineries: Controlling motors for pumps, compressors, and other equipment.

• Mining Operations: Controlling motors for conveyors, crushers, and other equipment.

• Commercial Buildings: Controlling motors for HVAC systems, pumps, and other equipment.

• Power Generation Plants: Controlling motors for pumps, fans, and other equipment.

Advantages of MCCs

MCCs offer several advantages over individual motor starters:

Centralized Control: Provides a central location for controlling and monitoring multiple motors.

• Reduced Wiring: Reduces the amount of wiring required compared to individual motor starters.

• Space Savings: Consolidates motor control equipment into a single enclosure, saving space.

• Improved Safety: Provides a safe and reliable means of disconnecting power to motors.

• Easy Maintenance: Simplifies maintenance and troubleshooting by providing easy access to motor control components.

• Automation Capabilities: Can be integrated with automation systems for remote control and monitoring.

• Standardization: Standardized design and construction simplifies installation and maintenance.

Selection Considerations

When selecting an MCC, consider the following factors:

• Voltage and Current Requirements: Determine the voltage and current requirements of the motors to be controlled.

• Number of Motors: Determine the number of motors to be controlled.

• Motor Starting Method: Select the appropriate motor starting method (e.g., across-the-line, reduced voltage).

• Control Requirements: Determine the control requirements for each motor (e.g., start/stop, speed control, reversing).

• Communication Requirements: Determine if communication capabilities are required for remote control and monitoring.

• Safety Requirements: Consider safety requirements, such as arc flash protection.

• Environmental Conditions: Consider the environmental conditions in which the MCC will be installed (e.g., temperature, humidity, dust).

• Standards Compliance: Ensure that the MCC complies with relevant standards, such as NEMA or IEC.

• Future Expansion: Consider the possibility of future expansion when selecting an MCC.

Maintenance of MCCs

Regular maintenance is essential for ensuring the reliable operation of an MCC. Key maintenance tasks include:

• Visual Inspection: Inspect the MCC for signs of damage, corrosion, or overheating.

• Cleaning: Clean the MCC to remove dust and debris.

• Tightening Connections: Tighten all electrical connections to prevent loose connections and overheating.

• Testing: Test the operation of the motor starters, overload relays, and other control devices.

• Insulation Resistance Testing: Perform insulation resistance testing to identify potential insulation failures.

• Thermographic Survey: Conduct a thermographic survey to identify hot spots and potential problems.

• Calibration: Calibrate overload relays and other protective devices.

• Component Replacement: Replace worn or damaged components.

• Arc Flash Hazard Analysis: Perform an arc flash hazard analysis to determine the appropriate personal protective equipment (PPE) for working on the MCC.

Conclusion

Motor Control Centers (MCCs) are essential components in industrial and commercial facilities for centralized control and protection of electric motors. They provide a convenient and organized way to manage motor starters, overload protection, and disconnects for a large number of motors. Proper selection, installation, and maintenance of MCCs are critical for ensuring the reliable and safe operation of electric motors.